Metal-coated Mirrors

Definition: mirrors where the reflection is obtained from a metal coating

More general term: mirrors

German: metallbeschichtete Spiegel

Categories:  general optics,

general optics,  photonic devices

photonic devices

Author: Dr. Rüdiger Paschotta

Cite the article using its DOI: https://doi.org/10.61835/z3f

Get citation code: Endnote (RIS) BibTex plain textHTML

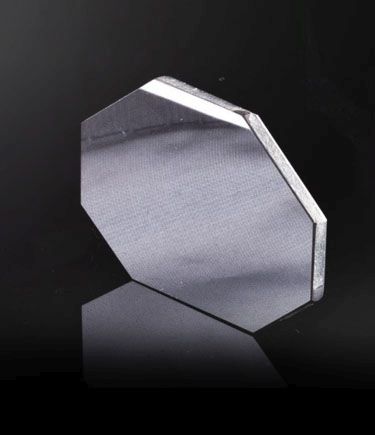

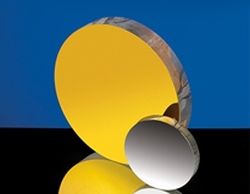

Metal-coated mirrors are mirrors (optical reflectors) based on a thin metal coating, produced e.g. with an vacuum evaporation or sputtering technique. The metallic coating is placed on a substrate, which is often consisting of a glass (e.g. fused silica), and sometimes a metal such as copper.

Common metal mirror coatings consist of thin films of aluminum, silver or gold; less common are beryllium, copper, chrome and various nickel/chrome alloys. The metallic coating is often protected (enhanced) with an additional dielectric layer.

The central features of metallic mirrors are very broadband reflections, although with a limited reflectivity, and low chromatic dispersion. Further, the angular dependence of the reflectivity is relatively weak.

Metal mirrors play a special role in infrared optics, i.e., in spectral regions where dielectric mirrors are hard to realize.

First Surface versus Second Surface Metallic Mirrors

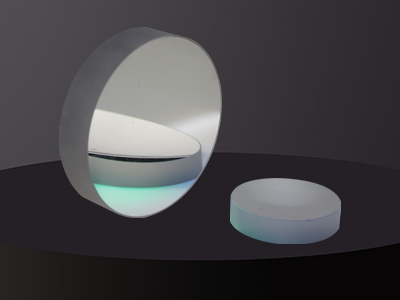

For a first surface mirror, the reflective coating is on the side of the incident light. The light only slightly penetrates the coating, but does not reach the substrate.

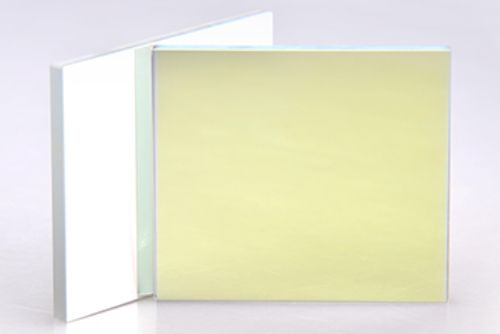

Second surface mirrors have the reflecting coating on the other side of the substrate, so that the coating can be better protected. The light propagates through the substrate before and after the reflection. This type of mirror is also common for household applications. In technical applications, problems can arise from the Fresnel reflection at the first surface (which can lead to ghost images, for example, and to some power losses), and in some applications from the chromatic dispersion of the glass.

The article on first surface mirrors contains more details.

Protected Mirrors

Often, the metal layer of a first surface mirror is covered with a thin layer or multiple layers of a dielectric material such as amorphous SiO2 (silica) or Si3N4 (silicon nitride), which protects the coating against oxidation (tarnish) and scratches. Such enhanced or protected mirror coatings are definitely more abrasion-resistant than uncoated ones, but still they tend to be more sensitive than dielectric mirrors. This implies that greater care is generally required for the cleaning of metal-coated optics; they may even have to be replaced when e.g. fingerprints have been made. Also, metallic mirrors are more or less sensitive to humidity and corrosive gases.

Multilayer protection coatings can also be used to enhance the reflectivity (see below); this leads to enhanced metal coatings e.g. for enhanced silver mirrors, also called protected silver mirrors. The resulting metal / dielectric coating effectively combines the large bandwidth of a metallic mirror with the higher reflectivity and damage threshold of a dielectric mirror. Note, however, that the chromatic dispersion can be substantially modified by such a multilayer coating.

Speculum Mirrors

Early mirrors where made from massive pieces of speculum metal, an alloy of two thirds copper and one third tin, which can be polished to obtain a smooth surface with high reflectivity. Such metal mirrors were used in telescopes, for example, They suffered from relatively rapid tarnishing, which made frequent re-polishing necessary. In the 19th century, such mirrors were largely replaced with silvered glass mirrors. These do not only exhibit less tarnishing, but also the glass provides are more rigid substrate, which is nevertheless less heavy. Since then, it became common to use only thin metallic coatings on substrates.

Broad Bandwidth, Low Chromatic Dispersion

A big advantage of metal-coated mirrors over dielectric mirrors is that the reflectivity is quite uniform over a wide spectral range and also quite insensitive to the angle of incidence and polarization. Also, metal-coated mirrors can be fabricated easily and are thus relatively cheap. Therefore, they are often used as general-purpose mirrors. Also, they are sometimes required for ultrashort pulses with ultrabroad bandwidth, where it is difficult to obtain sufficient reflection bandwidth from dielectric mirrors (although chirped dielectric mirrors nowadays also offer very large bandwidths). In that context, it also relevant that metal-coated mirrors exhibit very weak chromatic dispersion; the reflection phase-shift exhibits a very small wavelength dependence. This is useful, for example, for use as reference mirrors in white-light interferometers.

Metal-coated mirrors can also work for extremely long infrared wavelengths, e.g. up to 20 μm (→ infrared optics). In that region, it is difficult to work with dielectric mirrors, as dielectrics then exhibit strong absorption.

Limited Reflectivity

A disadvantage of metallic mirrors, when compared with dielectric mirrors, are the significant reflection losses. This limitation is of fundamental nature, as metals inevitably absorb some of the incident light (even if they are very pure). As a consequence, the reflectivity is limited, e.g. to roughly 98% for protected silver mirrors. Another consequence is the relatively low optical damage threshold: the absorbed light leads to heating, and as the heat is deposited in a quite thin layer, this can easily lead to damage. Both in terms of average power and peak power, the damage threshold is low. For high average powers, substantial thermal lensing and thermal beam distortions can arise from heating effects even well below the damage threshold.

The reflection losses may be reduced with dielectric multilayer coatings. Such enhanced coatings also lead to a correspondingly higher optical damage threshold. For example, the damage threshold of an enhanced coating silver mirror for nanosecond pulses from a 1064-nm YAG laser can be several J/cm2, whereas it may be only 0.5 J/cm2 for a simple protected silver mirror (and even much less for aluminum). For comparison, dielectric mirrors can stand several tens of J/cm2.

Partially Transmissive Mirrors

It is possible to obtain partial transparency of a metal coating by making it very thin. Such mirrors can also be used as beam splitters. However, the power losses are substantial, so that the sum of transmittance and reflectance is well below 1. It is more common to use dielectric mirrors for such applications, but partially transmissive metal-coated mirrors are used if a very high operation bandwidth is required and high power losses can be tolerated.

Common Mirror Materials

Protected aluminum mirrors, e.g. with a SiO2 coating, are used for many broadband applications in the visible and ultraviolet spectral region, reaching reflectivities well above 90% in the visible but often below 90% in the UV (similar to bare aluminum). Compared with silver mirrors, such enhanced aluminum mirrors have a lower tendency for tarnishing when exposed to humidity.

Protected silver coatings (again usually with a SiO2 coating) are similarly suitable for wavelengths from about 500 nm to 20 μm. Due to their lower reflection losses, they also exhibit substantially higher damage thresholds than aluminum mirrors. Therefore, they are often preferred for applications involving lasers.

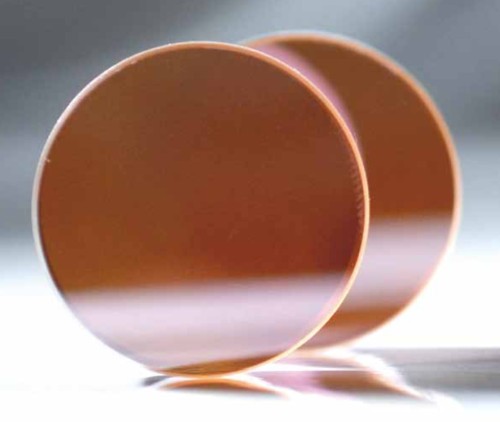

Gold mirrors are similar, but can be used only for about 600 nm and longer wavelengths. Here, reflectivities well over 95% (sometimes around 99%) are achieved. It is possible, for example, to obtain an average reflectivity of 97% between 700 and 2000 nm with a protected gold mirror. Sometimes, an unprotected gold mirror is preferred in order to avoid any dispersion from a protective coating; this is possible as gold does not tend to get oxidized.

Gold-coated copper mirrors (often fabricated with electrochemical techniques) can be used with high-power infrared lasers, such as CO2 lasers. Here, a thin reflecting gold coating is placed on a massive copper substrate. Substantial amounts of heat can be tolerated due to the high thermal conductivities of gold and copper.

More to Learn

Encyclopedia articles:

Suppliers

The RP Photonics Buyer's Guide contains 81 suppliers for metal-coated mirrors. Among them:

LASEROPTIK

LASEROPTIK offers standard mirror metal coatings such as aluminium, gold or silver, normally with protection layer or even enhanced, i.e. with an additional dielectric coating system.

UltraFast Innovations

UltraFast Innovations (UFI) offers a range of metal-coated mirrors, including so-called hybrid or enhanced metal coatings with additional dielectric layers for higher reflectance and protecting the metal against oxidation.

EKSMA OPTICS

EKSMA Optics offers a wide selection of various sizes of round, rectangular, spherical mirrors with protected gold, silver or aluminium coatings. Most of our metal-coated mirrors are available for quick delivery.

Shanghai Optics

Shanghai Optics provides custom metallic coatings which provide high reflection in some wavelength range, and are widely used in laser system and other optical elements. Our metallic coatings provide more effective and efficient spectral performance due to the low absorption properties. These mirror coatings can also be further customized to provide additional high pass or low pass wavelength performance in addition to the specified reflection band.

Ecoptik

Ecoptik offers metal-coated mirrors for various applications, in particular based on aluminum and gold. There is a wide choice of round, elliptical or custom shapes as well as flat, spherical, cylindrical and parabolic surfaces.

Avantier

Avantier offers custom metallic coatings that enable high reflection within specific wavelength ranges and are extensively utilized in optical elements and laser systems. Our metallic coatings are characterized by low absorption properties, which results in better and more efficient spectral performance. Additionally, these mirror coatings can be customized to deliver additional high pass or low pass wavelength performance, complementing the desired reflection band.

Edmund Optics

There is a wide range of metal-coated mirrors, including flat and focusing (concave) mirror, off-axis mirrors, specialty mirrors, broadband dielectric mirrors and other infrared mirrors.

Knight Optical

Knight Optical has a range of stock and custom metal-coated mirrors, including aluminium, silver or gold coated front surface mirrors available from stock.

Shalom EO

Metal-coated mirrors have many key features, including wide spectral range, low cost, non-sensitivity to the incidence angle and polarization state, relatively low scattering and low laser damage threshold.

Shalom EO offers a variety of metal-coated mirrors: BK7 metal-coated mirrors and UVFS metallic coated mirrors, with coating options like enhanced Al coating, protective Ag coating or protective Au coating and flatness options of λ/10 or λ/4. Both off-the-shelf and custom metal mirrors are offered.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

Share this with your friends and colleagues, e.g. via social media:

These sharing buttons are implemented in a privacy-friendly way!