Thin-film Polarizers

Acronym: TFP

Definition: optical polarizers based on a multilayer dielectric coating

German: Dünnschichtpolarisatoren

Author: Dr. Rüdiger Paschotta

Cite the article using its DOI: https://doi.org/10.61835/2uh

Get citation code: Endnote (RIS) BibTex plain textHTML

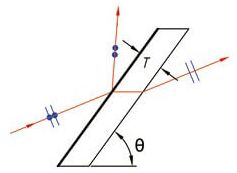

Thin-film polarizers are a kind of optical polarizers based on interference effects in a multilayer dielectric coating. That coating is usually placed on a glass plate. (A birefringent optical material as in various other types of polarizers is not needed.) A strongly polarization-dependent reflectivity is achieved for some range of incidence angles. (Basically always, s-polarized light is reflected and p-polarized light transmitted.) It is often convenient to design a thin-film polarizer such that it can be operated with an incidence angle of 45°, such that the reflected beam is obtained with an angular change of 90°. However, other incidence angles are also common.

There are different kinds of thin-film polarizers concerning optical fabrication technology and various properties which are of practical interest:

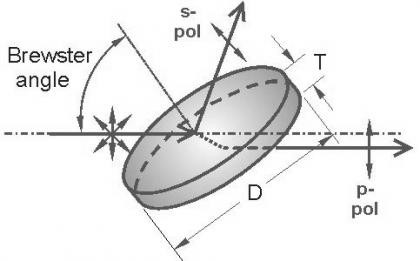

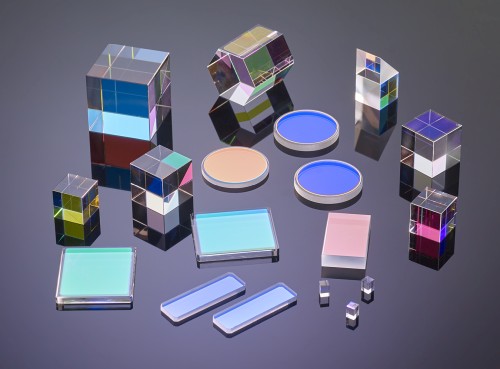

- Plate polarizers (Figure 1) consist only of a coated glass plate. The design is often made such that the angle of incidence is essential at Brewster's angle. In that way, reflection losses for the transmitted light on the back side are avoided easily. For other angles of incidence such as 45° (which is often convenient), an anti-reflection coating is required on the back side, and the layer structure design for the front side can also be more difficult.

- There are also polarizing cubes (Figure 2), which are obtained by coating a 45° prism and cementing another 45° prism to it, so that a cube is obtained. The input and output faces usually obtain anti-reflection coatings. The basic idea of the common MacNeille cube design [2] is to eliminate the reflection for p polarization by having Brewster's angle at all internal interfaces. It is then easy to obtain high reflectivity for s polarization with a simple Bragg mirror design without introducing a significant reflection for p polarization. The Brewster angle condition requires that a substrate material with suitable refractive index (for given coating materials) is chosen. Such designs work well in a large range of wavelengths, but only in a narrow angular range (typically a few degrees).

In other polarizing cube designs than the MacNeille design, one does not fulfill the Brewster angle condition but uses interference effects to suppress reflection for p polarization. Such interference polarizers typically operate well only in narrow wavelength ranges but give more flexibility concerning the used materials.

The cemented interface of a polarizing cube leads to a lower optical damage threshold of the order of 1 J/cm2 for nanosecond laser pulses. Optically contacted epoxy-free polarizing cubes, not requiring a cement, can stand several times higher fluences.

Since the interference effects in the multilayer coating are wavelength-dependent, a thin-film polarizer can work only in a limited wavelength range and angular range. However, operation in a range of tens or even a few hundred nanometers is possible by proper optimization of the thin film design. Such broadband polarizers, however, do not achieve the very high performance of narrowband polarizers (laser line polarizers), which are optimized for a narrow wavelength range. Figure 3 shows an example with a moderate operation bandwidth of 50 nm.

For the optimization of the coatings for thin-film polarizers, similar numerical techniques can be used as for designing broadband beam splitters or dichroic mirrors, for example.

An advantage of thin-film polarizers is that they can be made with rather large dimensions, which is more difficult with crystalline (birefringent) polarizers. It is thus possible to operate such high-power or high-energy devices with laser pulses at very high peak power levels.

More to Learn

Encyclopedia articles:

Suppliers

The RP Photonics Buyer's Guide contains 40 suppliers for thin-film polarizers. Among them:

Optogama

Optogama standard high contrast Brewster-type and 45° thin-film polarizers provide high extinction ratio Tp:Ts > 1000:1 thanks to the ion beam sputtered (IBS) thin-film coatings. Moreover, these polarizers are ideal for high-power levels and in the UV.

Optogama designs and manufactures standard and custom Brewster-type high contrast polarizers for the wavelength range between 230 nm and 2000 nm with face dimensions up to 160 mm.

Avantier

Avantier is capable of delivering a broad range of coatings, including anti-reflective, high reflective, and partial reflective coatings. Our coating offerings vary from simple anti-reflective coatings to intricate multilayer dielectric stacks. Examples of dielectric coatings include BBAR, V-coatings, dual wavelength coatings, and filters with sharp cut-on and cut-off wavelengths.

EKSMA OPTICS

EKSMA Optics has a wide range of BK7 and UV fused silica thin film laser polarizers for quick delivery. Thin film polarizers feature high laser damage thresholds and are designed for the most demanding applications with Nd host lasers operating in the 1040–1070 nm range and with femtosecond Ti:sapphire or Yb:KGW/KYW lasers.

LASEROPTIK

LASEROPTIK offers various types of polarizers, including thin-film (TFP) devices, cube polarizers (CP) and broadband polarizers (BBPOL). We can work in different wavelength ranges from the mid-IR (2.1 μm) to the UV (157 nm).

Artifex Engineering

Artifex Engineering offers custom dielectric thin-film polarizers with a high damage threshold. Our thin film polarizers are commonly used for Q-Switching and other high power applications. These components are dielectric coated glass substrates designed for use at the Brewster angle. Visit our product page for more information. We look forward to your inquiry.

OPTOMAN

OPTOMAN offers thin film polarizers, that are the optimal choice for polarizing high energy laser light. Thin Film Polarizers accomplish this task with a high efficiency level due to negligible absorption within the coating, transmittance (Tp) higher than 99%, and reflectance (Rs) as high as 99.99%.

OPTOMAN will provide an optimal solution in terms of extinction ratio (10'000:1 is possible), angle of incidence (various choices depending on application), and damage threshold ( > 49.4 J/cm2 @ 1064 nm, 10 ns, 100 Hz can be achieved in some configurations). Broadband configurations for femtosecond applications are also feasible.

Standard in-stock IBS coated polarizers can be found in OPTOSHOP.

Perkins Precision Developments

Perkins Precision Developments (PPD) manufactures Brewster’s angle polarizers as well as 45 degree plate polarizers for high performance with easy alignment. Because we utilize Ion Beam Sputtering (IBS) coating technology, our dielectric thin film plate polarizers are environmentally stable, thus there is no spectral shift caused by either time, moisture or temperature. The predictability and repeatability of IBS thin film coatings allow us to guarantee high transmission at a specific angle of incidence, eliminating the need to angle tune the optical component in order to achieve optimal performance.

As with all of our custom laser optics and polarizers, PPD's IBS coated polarizing beam splitters exhibit low absorption, high extinction (Tp/Ts) and high damage thresholds, making them ideal for use with high energy Nd:YAG and fibers lasers as well as other high-power pulsed and CW laser systems throughout the visible and near-infrared.

Shanghai Optics

Shanghai Optics can provide all types of anti-reflective, high reflective, and partial reflective coatings. We produce a wide variety of coatings from a single layer of anti-reflective coating to complex multilayer dielectric stacks. Types of dielectric coatings are BBAR, V-coatings, dual wavelength coatings, and sharp cut-on and cut-off filters.

Bibliography

| [1] | M. Banning, “Practical methods of making and using multilayer filters”, J. Opt. Sco. Am. 37 (10), 792 (1947); https://doi.org/10.1364/JOSA.37.000792 |

| [2] | S. M. MacNeille, “Beam Splitter”, U.S. Patent 2,403,731 (9 July 1946) |

| [3] | J. Mouchart et al., “Modified MacNeille cube polarizer for a wide angular field”, Appl. Opt. 28 (14), 2847 (1989); https://doi.org/10.1364/AO.28.002847 |

| [4] | Design of a thin-film plate polarizer with the RP Coating software |

| [5] | Design of a polarizing cube with the RP Coating software |

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

general optics

general optics

Connect and share this with your network:

Follow our specific LinkedIn pages for more insights and updates: