Diode-pumped Lasers

Author: the photonics expert Dr. Rüdiger Paschotta (RP)

Acronym: DPSSL = diode-pumped solid-state laser

Definition: solid-state lasers which are pumped with laser diodes

Category:

Related: laserslaser crystalssolid-state lasersall-solid-state laserslamp-pumped laserslaser diodesend pumpingside pumpinghigh-power lasersrod lasersslab lasersYAG lasers

Page views in 12 months: 3302

DOI: 10.61835/lnd Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

What are Diode-pumped Lasers?

Virtually all optically pumped lasers fall into one of two categories:

- lamp-pumped lasers, having some kind of gas discharge lamp (arc lamp or flash lamp) as the pump source

- diode-pumped lasers, which are pumped with some kind of laser diodes

This article treats the latter category.

Types of Diode-pumped Lasers

Most diode-pumped lasers are solid-state lasers (DPSSL = DPSS lasers = diode-pumped solid-state lasers). These are either bulk lasers, using some kind of laser crystal or bulk piece of glass, or fiber lasers (although the term DPSSL is less common for fiber lasers). Both categories span a range of output powers from a few milliwatts to multiple kilowatts (→ high-power lasers).

Less common are optically pumped semiconductor lasers (particularly VECSELs = vertical external cavity surface-emitting lasers), and there are also some relatively exotic types of diode-pumped gas lasers, e.g. alkali vapor lasers.

Types of Laser Diodes for Diode Pumping

There are different types of laser diodes which can be used for diode pumping, and differ substantially in terms of optical power:

- Low-power lasers (up to roughly 200 mW) can be pumped with small edge-emitting laser diodes. These exhibit an essentially diffraction-limited beam quality and make it fairly easy to achieve the same for the solid-state laser.

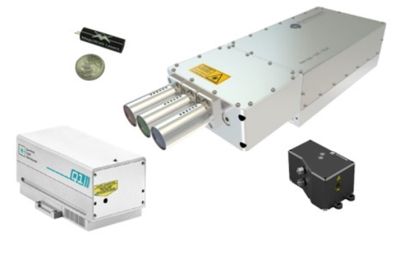

- Broad area laser diodes typically generate several watts and are suitable for end pumping solid-state lasers with output powers up to a few watts (see Figure 1). Their beam quality is substantially asymmetric, but normally still sufficient for achieving a diffraction-limited laser output without using complicated optics.

- High-power diode bars emit tens of watts (or even more than 100 W), allowing for higher output powers, particularly when several bars are combined. Their output beam is strongly asymmetric, and the beam quality is poor, so that their radiance (brightness) is much lower than that of lower-power diodes. Various types of beam shapers are used to symmetrize the beams. This makes it easier either to pump a bulk laser or to couple the light into a fiber.

- For the highest powers, diode stacks are often used. These have a still worse beam quality and lower brightness, but can provide multiple kilowatts. They are usually suitable only for side pumping.

In most cases, the pump diodes are operated continuously. This applies to all continuous-wave and mode-locked lasers, and also to many Q-switched lasers. However, quasi-continuous-wave operation with higher peak power for limited time intervals (e.g. 100 μs) is sometimes used for Q-switched lasers with a high pulse energy and low pulse repetition rate. Some pump diodes are explicitly optimized for such an operation mode.

Depending on the type of laser diode, different kinds of pump optics are used. It is also possible to use fiber-coupled diode lasers, which make it possible to separate the actual laser head from another package containing the pump diodes, so that the laser head can become very compact.

Designing Diode-pumped Lasers

Resonator design is a crucial issue for the development of a diode-pumped laser. The software RP Resonator is ideally suited for that. For power calculations, you can use the RP Fiber Power software — also for bulk lasers!

Advantages of Diode Pumping

The main advantages of diode pumping (in contrast to lamp pumping) are:

- A high electrical-to-optical efficiency of the pump source (of the order of 50%) leads to a high overall power efficiency (→ wall-plug efficiency) of the laser. As a consequence, small laser power supplies are needed, and both the electricity consumption and the cooling demands are drastically reduced, compared with those for lamp-pumped lasers.

- The narrow optical bandwidth of diode lasers makes it possible to pump directly certain transitions of laser-active ions without losing power in other spectral regions. It thus also contributes to a high efficiency and helps also to reduce problems with thermal lensing and other detrimental thermal effects.

- Although the beam quality of high-power diode lasers is not perfect, it often allows for end pumping of lasers with very good overlap of laser mode and pumped region, leading to high beam quality and power efficiency. In the domain of slab lasers, it allows edge pumping instead of face pumping, which brings important advantages.

- Diode-pumped low-power lasers can be pumped with diffraction-limited laser diodes. This allows the construction of very low-power lasers with reasonable power efficiency, i.e., with a very small electrical pump power, as is important for battery-powered devices.

- The lifetime of laser diodes is long compared with that of discharge lamps: typically many thousands of hours, often even well above 10 000 hours. However, various factors (e.g. voltage spikes, optical feedback and insufficient cooling) can lead to drastically reduced lifetimes. The exchange of laser diodes is also substantially more costly than that of discharge lamps.

- The compactness of the pump source, the power supply and the cooling arrangement makes the whole laser system much smaller and easier to use.

- Diode pumping makes it possible to use a very wide range of solid-state gain media for different wavelength regions, including e.g. upconversion lasers. For many solid-state gain media, the lower brightness of discharge lamps would not be sufficient.

- The low intensity noise of laser diodes leads to low noise of the diode-pumped laser.

Achievements

The benefits of diode pumping have led to amazing achievements. Some examples are:

- There are miniature solid-state lasers with excellent efficiency, beam quality, spectral purity, and stability. Some of those may even be battery-powered.

- Diode-pumped high-power solid-state lasers can deliver kilowatt output powers with fairly high beam quality. This applies particularly to thin-disk lasers, but also to high-power fiber lasers and amplifiers.

- Diode pumping is also essential for a large variety of mode-locked lasers, generating e.g. well over 100 W of average output power in sub-picosecond pulses, or picosecond pulses for telecom applications with a pulse repetition rate up to 50 GHz.

Limitations

In the early years of diode pumping, the output powers achievable were very limited – smaller than those of lamp-pumped lasers. In the meantime, however, high-power diode bars and diode stacks have become very powerful, and the highest output powers are now usually achieved with diode pumping.

The main disadvantage of diode pumping (as compared with lamp pumping) is the significantly higher cost per watt of pump power. This is severe for high powers, and particularly for generating high-energy pulses where a rather high pump power is required for limited time. For this reason, lamp pumping is still used in cases where high powers and particularly high pulse energies are needed. For some applications, even joule-level pulse energies and many tens of kilowatts of pump power are required, while low repetition rates (e.g. 10 Hz) make the thermal effects manageable and the low power conversion efficiency acceptable.

Laser diodes are electrically less robust than discharge lamps. They may e.g. be quickly destroyed by excessive drive currents, or by electrostatic discharges. In conjunction with properly designed electronics, however, this should not happen. Problems can also arise from optical feedback.

Applications

Diode-pumped solid-state lasers have a very wide range of applications. Indeed, they are used in all of the areas mentioned in the article on laser applications.

Frequently Asked Questions

This FAQ section was generated with AI based on the article content and has been reviewed by the article’s author (RP).

What is a diode-pumped laser?

A diode-pumped laser is a type of laser that uses one or more laser diodes as the optical pump source to excite the gain medium, as opposed to older technologies which often use gas discharge lamps.

What does DPSSL stand for?

DPSSL stands for diode-pumped solid-state laser. It is the most common type of diode-pumped laser, where the gain medium is a solid-state material like a laser crystal or a piece of doped glass.

What are the main advantages of diode pumping over lamp pumping?

Diode pumping offers significantly higher power efficiency, a more compact system size, and a longer lifetime for the pump source. It also enables better laser beam quality and lower noise.

How does diode pumping improve a laser's efficiency?

Laser diodes are highly efficient at converting electricity into light. Furthermore, their narrow emission bandwidth allows them to precisely target the absorption peak of the gain medium, reducing waste heat and improving overall efficiency.

What are the main limitations of diode-pumped lasers?

The primary disadvantage compared to lamp-pumped systems is the higher cost per watt of pump power. Laser diodes are also electrically more fragile and can be damaged by electrostatic discharges or excessive currents if not properly handled.

Are all diode-pumped lasers solid-state lasers?

While most are solid-state lasers (DPSSLs), there are other types, including diode-pumped semiconductor lasers (like VECSELs) and even some diode-pumped gas lasers.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 129 suppliers for diode-pumped lasers. Among them:

Bright Solutions offers a range of diode-pumped solid-state lasers, including

- Wedge — nanosecond Q-switched lasers for 266, 355, 532, 1064, 1570, 3100 nm (also multi-wavelength configurations), used e.g. for atmospheric LIDAR, monitoring, glass machining or lithography

- Onda — compact monolithic nanosecond Q-switched lasers for 266, 355, 532 or 1064 nm, used e.g. for lens marking, plastic marking or intravolume glass marking

- Sol — compact Q-switched lasers for 355, 532 or 1064 nm, up to 200 kHz, used e.g. for automotive fabrication, electronic machining, ID card writing and other industrial applications

- Vento — sub-nanosecond MOPA lasers with pulse durations down to 500 ps, up to 200 kHz, up to 100 W average power at 1064 nm or 50 W at 532 nm, e.g. for LIDAR or PCB microprocessing

- Aero — high energy lasers with up to 200 mJ at 1064 nm, 100 mJ at 532 nm, multi-wavelength configurations, custom beam shaping, application e.g. in atmospheric LIDAR, LIBS or nonlinear spectroscopy

- BDL and BFD — fiber-coupled diode laser modules with up to 200 W cw (or 400 W quasi-cw) in a 200-μm core fiber, e.g. for pumping of solid-state and fiber lasers, material processing or illumination; pulsed models are available

- NPS — narrowband picosecond lasers for applications like OPO pumping, Raman or fluorescence spectroscopy and multimodal imaging

- ONE DPSS — miniaturized Q-switched lasers with up to 200 μJ and down to 3 ns, e.g. for atmospheric LIDAR and laser marking on plastics

Monocrom offers diode-pumped solid state lasers for medical, material processing, LiDAR and spectroscopy applications as well as for laser pumping:

- LQ-527-12: a frequency-doubled Nd:YLF laser emitting up to 1 mJ at 527 nm

- Multi-Path 532: a photocoagulation laser emitting up to 8 W cw or 15 W qcw at 532 nm

- CiOM lasers emitting nanosecond pulses at 526.5 nm

CNI offers the widest range of diode-pumped lasers not only in terms of wavelength, but also concerning various features: we have single-frequency lasers, narrow linewidth lasers, low noise lasers, high power and energy lasers, mode-locked and picosecond lasers and Q-switched lasers.

The large range of Lumibird pulsed nanosecond solid-state lasers includes diode-pumped models, from 5 mJ to 1.5 J at 1064 nm, from single pulse to 400 Hz. These lasers can be integrated into a system thanks to their compactness and robustness, or used as stand-alone devices. Several wavelengths are available, including 1.57 µm.

As a breakthrough in DPSS laser technology, the MirPac is a 2.94-μm Er:YAG laser with TEM00 output beam in a hermetically sealed windowed package that was the first of its kind. Operating at 2940 nm, the wavelength with strongest absorption in water, the MirPac is ideal for use in tandem with water or with materials that contain some amount of water.

Vertical-External-Cavity Surface-Emitting Lasers (VECSELs), also known as semiconductor disk lasers or optically pumped semiconductor lasers, provide a versatile platform with features beneficial for applications requiring broad wavelength coverage and high output power. Key features include:

- Broad wavelength coverage

- Multi-watt power output

- Low noise

- Excellent spatial quality

- Tunable narrow-linewidth operation

VECSELs are suitable for applications that demand exotic wavelengths and high power with narrow spectral linewidths.

CSRayzer's high quality pump laser diodes with butterfly package can provide high output powers for fiber amplifiers. The built-in thermo-electric cooler (TEC) can make the laser diode work properly in various environments.

Serving North America, RPMC Lasers offers diode-pumped lasers in pulsed and CW configs, customizable, compact, rugged, with varied power for diverse uses.

Our Pulsed DPSS lasers feature UV, visible, IR wavelengths to 5th harmonic, active/passive Q-switching for ns, ps & fs pulses, pulse energies from nJ to 100s of mJ, from single pulse to 80 MHz repetition rate, high brightness, and efficient absorption.

Our CW DPSS lasers provide UV to NIR options, single/multimode, narrow linewidth, stabilized outputs, integrated thermal/electrical modules, OEM or plug-and-play setups with free-space/fiber output from mW to watts.

Let RPMC help you find the right laser today!

Teem Photonics offers air-cooled diode-pumped passively Q-switched lasers — the Microchip laser series and the more powerful Powerchip laser series. Higher average power versions are based on a MOFA architecture, i.e., using a fiber amplifier. All can generate intense sub-nanosecond pulses. Available emission wavelengths are 1064 nm, 532 nm, 355 nm, 266 nm and 213 nm.

ALPHALAS offers advanced diode-pumped solid-state lasers with pulse durations in the nanosecond or picosecond region, as well as CW lasers. Different types of pulsed diode-pumped lasers include:

- actively or passively mode-locked picosecond lasers,

- regeneratively amplified lasers,

- actively and passively Q-switched lasers, and

- mode-locked and cavity-dumped lasers.

Customer-specific repetition rates and pulse energies are available on request. Some models can operate at single longitudinal mode in CW or pulsed mode. Optionally available are also second, third or fourth harmonics for most of the above lasers.

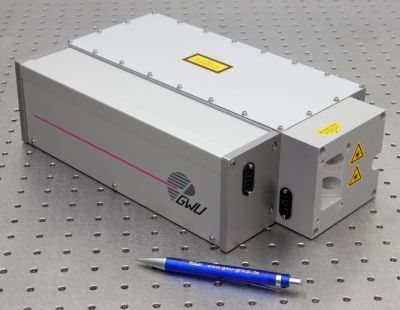

GWU-Lasertechnik provides diode-pumped solid-state laser solutions with wavelength conversion. The sophisticated optical and mechanical design and the soft pumping scheme ensure excellent performance, highest reliability and longest lifetime. Continuous, gap-free tunability from the deep-UV at < 190 nm to the infrared spectral range at > 2700 nm is offered for best usability.

HÜBNER Photonics specializes in providing high-quality continuous-wave diode-pumped lasers (DPLs) suitable for a range of applications. These lasers are available in wavelengths from 355 nm to 1064 nm and are designed for single-longitudinal mode operation, ensuring excellent noise and power stability.

For more detailed specifications and potential applications, please visit the HÜBNER Photonics website.

Bibliography

| [1] | R. J. Keys, “Injection luminescent pumping of CaF2:U3+ with GaAs diode lasers”, Appl. Phys. Lett. 4, 50 (1964); doi:10.1063/1.1753958 (first diode-pumped laser) |

| [2] | R. L. Byer, “Diode laser-pumped solid-state lasers”, Science 239, 742 (1988); doi:10.1126/science.239.4841.742 |

| [3] | D. W. Hughes and J. R. M. Barr, “Laser diode pumped solid state lasers”, J. Phys. D: Appl. Phys. 25 (4), 563 (1992); doi:10.1088/0022-3727/25/4/001 |

| [4] | C. A. Wang and S. H. Groves, “New materials for diode laser pumping of solid-state lasers”, IEEE J. Quantum Electron. 28 (4), 942 (1992); doi:10.1109/3.135213 |

| [5] | D. C. Hanna and W. A. Clarkson, “A review of diode-pumped lasers”, in Advances in Lasers and Applications (eds. D. M. Finlayson and B. Sinclair), Taylor & Francis, New York (1999) |

| [6] | W. Koechner, Solid-State Laser Engineering, 6th edn., Springer, Berlin (2006) |

(Suggest additional literature!)

This encyclopedia is authored by Dr. Rüdiger Paschotta, the founder and executive of RP Photonics AG. How about a tailored training course from this distinguished expert at your location? Contact RP Photonics to find out how his technical consulting services (e.g. product designs, problem solving, independent evaluations, training) and software could become very valuable for your business!