Laser Diodes

Author: the photonics expert Dr. Rüdiger Paschotta (RP)

Acronym: LD

Definition: semiconductor lasers with a current-carrying p–n junction as the gain medium

Categories:

Related: diode laserssemiconductor lasersdistributed feedback lasersdistributed Bragg reflector lasersbroad area laser diodesdiode barsdiode stackshigh-brightness laser diodesexternal-cavity diode laserssurface-emitting semiconductor laserslaser diode modulesfiber-coupled diode lasers

Page views in 12 months: 6435

DOI: 10.61835/m3d Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

What are Laser Diodes?

Laser diodes are electrically pumped semiconductor lasers in which the gain is generated by an electric current flowing through a p–n junction or (more frequently) a p–i–n structure. In such a heterostructure of a bipolar interband laser, electrons and holes can recombine, releasing the energy portions as photons. This process can be spontaneous, but can also be stimulated by incident photons, in effect leading to optical amplification, and, with optical feedback in a laser resonator, to laser oscillation. The article on semiconductor lasers describes in more detail how the laser amplification process in a semiconductor works.

Diode lasers are lasers based on one or several laser diodes, and possibly auxiliary parts, e.g. for cooling.

Most semiconductor lasers are based on laser diodes, but there are also some types of semiconductor lasers which do not require a diode structure and thus do not belong to the category of diode lasers. In particular, there are quantum cascade lasers and optically pumped semiconductor lasers. The latter can be made of undoped semiconductor materials which cannot conduct significant electric currents.

Types of Laser Diodes

Most laser diodes (LDs) are built as edge-emitting lasers, where the laser resonator is formed by coated or uncoated end facets (cleaved edges) of the semiconductor wafer. They are often based on a double heterostructure, which restricts the generated carriers to a narrow region and at the same time serves as a waveguide for the optical field (double confinement). The current flow is restricted to the same region, sometimes using isolating barriers. Such arrangements lead to a relatively low threshold pump power and high efficiency. The active region is usually quite thin — often so thin that it acts as a quantum well. In some cases, quantum dots are used.

Some modern kinds of LDs are of the surface-emitting type (see below), where the emission direction is perpendicular to the wafer surface, and the gain is provided by multiple quantum wells.

There are very different kinds of LDs, operating in very different regimes of optical output power, wavelength, bandwidth, and other properties:

- Small edge-emitting LDs generate between a few milliwatts and up to roughly half a watt of output power in a beam with high beam quality. The output may be emitted into free space or coupled into a single-mode fiber (→ fiber-coupled diode lasers). Such lasers can be designed to be either index guiding (with a waveguide structure guiding the laser light within the LD) or gain guiding (where the beam profile is kept narrow via preferential amplification on the beam axis).

- For small LDs made as Fabry–Pérot laser diodes or more specifically as distributed Bragg reflector lasers (DBR lasers) with short resonators, one may achieve single-frequency operation. More reliable single-frequency operation can be achieved with distributed feedback lasers (DFB lasers). In some cases one also achieves substantial wavelength tunability.

- External cavity diode lasers contain a laser diode as the gain medium of a longer laser resonator, completed with additional optical elements such as laser mirrors or a diffraction grating. They are often wavelength-tunable and exhibit a small emission linewidth.

- Broad area laser diodes (also often called broad stripe laser diodes or wide stripe lasers) generate up to a few watts of output power. The beam quality is significantly poorer than that of lower-power LDs, but better than that of diode bars (see below).

- high-brightness laser diodes are laser diodes which are optimized for a particularly high radiance (brightness). Different technologies may be used, and such lasers are available on quite different power levels.

- Slab-coupled optical waveguide lasers (SCOWLs), containing a multi-quantum well gain region in a relatively large waveguide, can generate a watt-level output in a diffraction-limited beam with a nearly circular profile.

- High-power diode bars contain an array of broad-area emitters, generating tens of watts with poor beam quality. Despite the higher power, the brightness is lower than that of a broad area LD.

- High-power stacked diode bars (→ diode stacks) are stacks of multiple diode bars for the generation of extremely high powers of hundreds or thousands of watts.

- Monolithic surface-emitting semiconductor lasers (VCSELs) typically generate a few milliwatts with high beam quality. There are also external-cavity versions of such lasers (VECSELs) which can generate much higher powers with still excellent beam quality. Finally, there are photonic crystal surface-emitting lasers, which can combine the performance of a VECSEL with a monolithic setup and electrical pumping.

Laser diodes may emit a beam into free space, but many LDs are also available in fiber-coupled form. The latter makes it particularly convenient to use them, e.g., as pump sources for fiber lasers and fiber amplifiers.

Emission Wavelengths

The emission wavelength of a laser diode is essentially determined by the band gap of the laser-active semiconductor material: the photon energy is close to the band gap energy. In quantum well lasers, there is also some influence of the quantum well thickness. A variety of semiconductor materials makes it possible to cover wide spectral regions. In particular, there are many ternary and quaternary semiconductor compounds, where the bandgap energy can be adjusted in a wide range simply by varying the composition details. For example, an increased aluminum content (increased x) in AlxGa1-xAs causes an increase in the bandgap energy and thus a shorter emission wavelength. Table 1 gives an overview of typical material systems.

| Laser diode material (active region / substrate) |

Typical emission wavelengths | Typical application |

|---|---|---|

| InGaN / GaN, SiC | 380, 405, 450, 470 nm | data storage |

| AlGaInP / GaAs | 635, 650, 670 nm | laser pointers, DVD players |

| AlGaAs / GaAs | 720–850 nm | CD players, laser printers, pumping solid-state lasers |

| InGaAs / GaAs | 900–1100 nm | pumping EDFAs and other fiber amplifiers; high-power VECSELs |

| InGaAsP / InP | 1.2–2.0 μm | optical fiber communications, sensing, spectroscopy |

| AlGaAsSb / GaSb | 1.8–3.4 μm | defense, sensing, spectroscopy |

Table 1: Emission wavelengths of various common types of laser diodes.

Note that there are some laser diodes operating outside the spectral regions given in the table. For example, InGaN lasers may be optimized for longer emission wavelengths, reaching the green spectral region, although typically with lower performance. Besides, there are e.g. lead salt diodes for generating mid infrared light.

Most laser diodes emit in the near-infrared spectral region, but others can emit visible (particularly red or blue) light or mid-infrared light.

Emission Bandwidth and Wavelength Tuning

Most LDs emit a beam with an optical bandwidth of a few nanometers. This bandwidth results from the simultaneous oscillation of multiple longitudinal (and possibly transverse) resonator modes (multimode laser diodes). Some other kinds of LDs, particularly distributed feedback lasers, operate on a single resonator mode (→ single-frequency operation), so that the emission bandwidth is much narrower, typically with a linewidth in the megahertz region. Further linewidth narrowing is possible with external cavities and particularly with narrowband optical feedback from a reference cavity (→ frequency-stabilized lasers).

The emission wavelength (center of the optical spectrum) of multimode LDs is usually temperature sensitive, typically with an increase of ≈ 0.3 nm per 1 K temperature rise, resulting from the temperature dependence of the gain maximum. (The temperature influences the thermal population distributions in the valence and conduction band.) For that reason, the junction temperature of LDs for diode pumping of solid-state bulk lasers has to be stabilized, if the absorption bandwidth of the laser crystal is narrow (e.g. only a few nanometers wide). It is also possible to tune the emission wavelength via the junction temperature.

The emission wavelength also reacts to changes in the drive current — essentially just because of the induced temperature change. The current dependence thus depends on details like how the laser diode is cooled.

Single-mode diodes can have a significantly smaller temperature coefficient of the emission wavelength, as the resonance frequencies react less to temperature changes than the optical gain does. For applications in scanning laser absorption spectroscopy, the wavelength is sometimes scanned by operating the laser intermittently. The temperature then rises during each current pulse and causes the optical frequency to fall. The wavelength of external-cavity lasers can also be tuned, e.g. by rotating the diffraction grating in the laser cavity.

Voltage–Current Characteristics

Laser diodes have voltage–current characteristics like other semiconductor diodes. A substantial current flows only above a certain critical voltage, which depends on the used material system. (The critical voltage is roughly proportional to the bandgap energy of the material and also depends somewhat on the device temperature.) Above the critical voltage, the current rises rapidly with increasing voltage.

(For comparison, the photon energy for 808 nm is 1.53 eV.) Note that this curve is shifted to the right for increasing device temperature; one then obtains a higher current for the same voltage.

A laser diode is normally not operated by applying a fixed voltage because the flowing current could then very sensitively depend on that voltage, and could also be substantially affected by the device temperature. There could even be a catastrophic runaway effect: a high current could lead to a strong temperature rise, which could further increase the current, finally destroying the diode. Therefore, in practice one usually uses a laser diode driver which stabilizes a certain current; this means that it automatically adjusts the voltage such that the desired current is obtained. Alternatively, one uses a constant power mode, where the drive current is automatically adjusted for achieving the desired output power.

Note that the current rather than the voltage determines the rate with which carriers are injected into the laser diode. Therefore, there is a strong relation between the flowing current and the emitted optical power. There is essentially no output power below a certain threshold current, and above the laser threshold the output power grows roughly in proportion to the current minus the threshold current.

Power Conversion Efficiency

Diode lasers can reach high electrical-to-optical efficiencies — typically of the order of 50%, sometimes above 60% or even above 70% [7]. At reduced operating temperatures, even around 80% are possible [10]. The efficiency is usually limited by factors such as the electrical resistance, carrier leakage, scattering, absorption (particularly in doped regions), and spontaneous emission. Particularly high efficiencies are achieved with laser diodes emitting e.g. around 940–980 nm (as used e.g. for pumping ytterbium-doped high-power fiber devices), whereas 808-nm diodes are somewhat less efficient.

The highest power conversion efficiency is typically achieved not for the highest output power, but for a somewhat reduced output power because the required voltage is then lower.

Beam Quality and Beam Shaping

Some low-power LDs can emit beams with relatively high beam quality (even though the high beam divergence requires some care to preserve that during collimation). Most higher-power LDs, however, exhibit a relatively poor beam quality, combined with other non-favorable properties, such as a large beam divergence, high asymmetry of beam radius and beam quality between two perpendicular directions, and astigmatism. It is not always trivial to find the best design for beam shaping optics, being compact, easy to manufacture and align, preserving the beam quality and avoiding interference fringes, removing astigmatism, having low losses, etc. Typical parts of such diode laser beam shaping optics are collimating lenses (spherical or cylindrical), apertures and anamorphic prism pairs.

Beam Combining

As the light emitted by a laser diode is linearly polarized, it is possible to combine the outputs of two diodes with a polarizing beam splitter, so that an unpolarized beam with twice the power of a single diode but the same beam quality can be obtained (polarization multiplexing). Alternatively, it is possible to combine the beams of LDs with slightly different wavelengths using dichroic mirrors (→ spectral beam combining). More systematic approaches of beam combining allow combining a larger number of emitters with a good output beam quality. Advances in that field have much contributed to the possibility of using direct-diode lasers e.g. in laser material processing.

Pulse Generation

Although the most common mode of operation of LDs is continuous-wave operation, many LDs can also generate light pulses. In most cases, the principle of pulse generation is gain switching, i.e. modulating the optical gain by switching the pump current. Small diodes can also be mode-locked for generating picosecond or even femtosecond pulses. Mode-locked laser diodes can be external-cavity devices or monolithic, in the latter cases often containing different sections operated with different current.

Noise Properties

Different types of diodes have very different noise properties. The intensity noise is typically close to quantum-limited only well above the relaxation oscillation frequency, which is very high (often several gigahertz). However, some low-power LDs operated at cryogenic temperatures have been demonstrated to exhibit even significant amplitude squeezing, i.e., intensity noise well below the shot noise limit. In all semiconductor lasers, intensity noise is generally coupled to phase noise, making these noise properties strongly correlated.

As mentioned above, linewidth values are very different. Multimode LDs exhibit a lot of excess noise associated with mode hops. Noise in different modes can be strongly anti-correlated, so that the intensity noise in single modes can be much stronger than the noise of the combined power. This has the important consequence that the intensity noise can be increased when the beam e.g. of a diode bar is truncated at an aperture or spectrally filtered.

The laser diode driver can also contribute a lot to the laser noise because even very fast current fluctuations can be transformed into intensity and phase fluctuations in the generated light.

Packaging of Laser Diodes

Laser diodes may be supplied as bare semiconductor chips, but are more commonly delivered in some kind of packaged form that provides electrical contacts, heat sinking, and optical access.

Typical forms of packaging for laser diodes are:

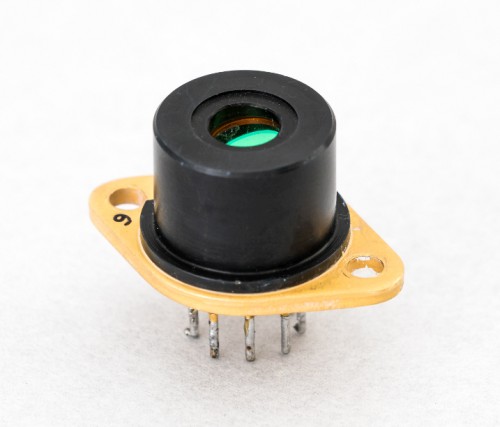

TO-can Packages

TO-can packages such as TO-56 or TO-46 are package types originally developed for simple electronic components like transistors, and are widely used for low- to medium-power laser diodes. They consist of a compact, roughly cylindrical metal cap mounted on a circular metal header with a small number of pins. For laser diodes, there are typically three leads for the diode and case connection, with possible additional leads for a monitor photodiode or a small thermoelectric cooler.

For free-space optical output, the cap usually incorporates an optical window through which the laser beam emerges opposite to the pins. An additional lens or (more commonly) a lens window can serve for beam collimation. Devices intended for particularly low cost or special integration may instead use an “open-can” configuration without a window.

TO-packaged laser diodes may also contain a thermistor and sometimes a miniature thermoelectric cooler (TEC for temperature control, although high-precision temperature stabilization is more commonly implemented in larger package types.

TO-can packages are widely used in consumer devices (e.g., for optical storage or in laser pointers), as low-power pump sources, and in cost-sensitive instrumentation. Their limitations include modest heat dissipation capability, limited space for micro-optics, and comparatively low fiber coupling efficiency relative to dedicated fiber-coupled packages.

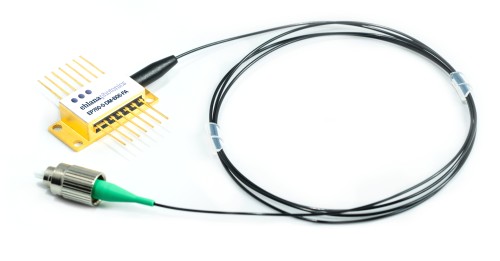

Butterfly Packages

Butterfly-style packages are rectangular, hermetic metal housings with rows of electrical pins on each side and one or sometimes several permanently attached optical fibers of suitable type: for low-power diodes, often simple single-mode or polarization-maintaining fibers, for higher powers multimode fibers.

Such packages are widely used for telecommunication-grade DFB and DBR diodes, precision pump lasers and other high-stability sources.

Inside such a package, one or several laser chips are mounted on a submount with a thermoelectric cooler and a thermistor for accurate temperature control. Micro-optics (for example, collimating and focusing lenses, fast-axis correction optics, and sometimes optical filters) are used to couple the light efficiently into the output fiber. A monitor photodiode is typically included for power stabilization, and some models also incorporate a Faraday isolator to reduce sensitivity to back-reflections.

These packages provide robust fiber coupling, excellent thermal management, and high reliability, making them a standard choice for telecom systems and precision instrumentation. They are, however, larger and more expensive than TO-can packages.

C-mount and Other Open Heatsink Packages

For higher-power single-emitter laser diodes, simple open heatsink packages such as the C-mount are widely used. Here, the laser chip is soldered directly onto a small copper or copper–tungsten block shaped to allow mechanical attachment to a larger heatsink. Electrical contacts are provided by bond wires and a small number of pins or solder tabs.

Such packages offer low thermal resistance and easy optical access to the laser facet, which is advantageous for custom micro-optics (e.g. fast-axis collimation, beam shaping) and for laboratory setups. However, the chip is mechanically and environmentally more exposed than in hermetic housings, so adequate environmental protection and cleanliness must be provided at the module or system level.

High-power Diode Bars and Stacks

High-power laser diodes are often manufactured as diode bars, which are long, narrow chips containing many emitters in parallel along a ≈1 cm length. These bars are typically soldered onto ceramic or metal-ceramic submounts and then onto larger copper or copper–tungsten heat spreaders. The resulting packages are designed primarily for efficient removal of large heat loads rather than for compactness.

Common formats include:

- Conduction-cooled bars and arrays, mounted on copper blocks or standardized modules that can be clamped to external heatsinks.

- Microchannel-cooled packages, where the bar is mounted on a substrate containing internal fluid channels, enabling very high heat-flux removal for multi-hundred-watt or kilowatt-class operation.

- Stacked arrays (two-dimensional stacks of bars), used as pump sources for high-power solid-state lasers and fiber lasers, often with dedicated fast-axis collimation optics for each bar and additional beam-combining optics.

Packaging challenges for bars and stacks include managing strong thermal gradients and mechanical stress, maintaining facet reliability at high optical power densities, and integrating the required fast-axis and slow-axis correction optics in a mechanically stable way.

Chip-on-submount (CoS) / Bare-die Assemblies

Instead of full packages, many laser diodes are offered as chips mounted on ceramic or metal-ceramic submounts with bond pads (chip-on-submount), or even as bare dies. This approach is useful for OEM integration into custom modules, photonic integrated circuits, or compact multi-emitter assemblies, where the customer designs the higher-level package.

In such cases, the system integrator is responsible for providing suitable environmental protection (often via a hermetic module), adequate thermal management, and electrostatic discharge (ESD) and overdrive protection, as well as for integrating and stabilizing any required micro-optics and, where relevant, fiber coupling.

Device Lifetime and Reliability

When operated under proper conditions, diode lasers can be very reliable during lifetimes of tens of thousands of hours. However, much shorter lifetimes can result from a number of factors, such as operation at too high temperatures (e.g. caused by insufficient cooling) and current or voltage spikes, e.g. from electrostatic discharge or ill-designed laser drivers.

There are different failure modes, including catastrophic optical damage (COD) (with complete device destruction within milliseconds or less) and steady degradation due to effects like oxidation of the output facet, growth of dislocations in the semiconductor structure, diffusion of metal from electrodes and degradation of heat sinks. Apart from the operation conditions, various design factors strongly influence the lifetime. For example, designs with aluminum-free active regions have been found to have superior reliability and lifetimes, and certain coatings (or just additional semiconductor layers) on optical surface can also be very helpful. The details of some advanced diode designs have not been disclosed by manufacturers to maintain a competitive advantage.

In order to improve device lifetimes, LDs are often operated at reduced current levels (and thus output powers). Moderate power reductions can at the same time increase the wall-plug efficiency due to the lower junction voltage, whereas stronger reductions reduce the efficiency.

A high reliability of laser diodes can be achieved not only by optimizing their design, but also by applying testing procedures, e.g. during burn-in tests and other types of quality control. See the article on laser diode testing for more details.

Applications

Laser diodes are used in a very wide range of applications. The following list gives some important examples:

- Low-power single-mode LDs with high beam quality are used for data recording and reading on CD-ROMs, DVDs, Blu-ray Discs, and holographic data storage media. Such lasers can operate in different spectral domains from the infrared to the blue and violet region, with the shorter wavelengths allowing for higher recording densities.

- Single-mode LDs including VCSELs are widely used in optical fiber communications, particularly in data transmitters. In some cases, the data modulation is done directly via the drive current.

- Single-mode LDs are also applied in laser spectroscopy (TDLAS) with very compact low-power measurement devices.

- Small red laser diodes (→ red lasers) are used in laser pointers.

- Distance measurements are often done with modulated low-power diode lasers. Similar lasers are used in laser printers, scanners and bar code readers.

- Broad area laser diodes, diode bars and diode stacks are often used for diode pumping of solid-state lasers. Fiber-coupled broad area LDs also serve as pump sources of fiber amplifiers.

- Some kinds of surgery (e.g. treatment of enlarged prostates) and dermatological therapies can be done with radiation from diode bars.

- High-power diode stacks are directly used in laser material processing in cases where a high beam quality is not required, e.g. for surface hardening, welding and soldering. Compared with other high-power lasers, they are simpler and have a much better wall-plug efficiency.

In terms of sales volumes, the applications in optical data storage and telecommunications are very dominating. The third most important application, which is pumping of solid-state lasers, already has sales volumes which are nearly an order of magnitude lower than the previously mentioned sectors.

Low-power laser diodes generate the largest revenues of all laser types — mainly due to applications in communications and data storage. High-power laser diodes have far lower sales numbers and volumes, and are used mainly for displays (with fast growth), medical and military applications. Direct use of high-power laser diodes for material processing (direct-diode lasers) has a small volume so far, but exhibits rapid growth.

Related Devices

LDs are often used in the form of laser diode modules, containing a variety of additional components e.g. for beam shaping and cooling and protection of the LD, and wavelength conversion.

A semiconductor optical amplifier (SOA) has a setup which is similar to an LD, but the end reflections are suppressed. Without an input signal, such a device can act as a superluminescent diode (SLD), generating light via amplified spontaneous emission. The optical spectrum is then smooth and normally much broader.

Light-emitting diodes (LEDs) use the same mechanism of generating photons as LDs, but they usually do not exhibit significant optical amplification (laser gain). So-called resonant-cavity LEDs do exploit some degree of stimulated emission, and are in this sense intermediate between ordinary LEDs and SLDs.

Frequently Asked Questions

This FAQ section was generated with AI based on the article content and has been reviewed by the article’s author (RP).

What is a laser diode?

A laser diode is an electrically pumped semiconductor laser. An electric current flowing through a p–n or p–i–n junction causes electrons and holes to recombine, which can lead to stimulated emission of photons and thus laser action.

What is the difference between a laser diode and a diode laser?

A laser diode is the semiconductor component itself. The term 'diode laser' refers to a complete laser system based on one or more laser diodes, which may include optics, cooling equipment, and a power supply.

Are all semiconductor lasers also laser diodes?

No. While most are, some types like quantum cascade lasers and optically pumped semiconductor lasers do not use a diode structure for electrical pumping and are therefore not classified as laser diodes.

How is the emission wavelength of a laser diode determined?

The emission wavelength is primarily determined by the band gap energy of the semiconductor material in the active region. By using different material compositions, such as AlGaAs or InGaN, a wide range of wavelengths can be produced.

How can the wavelength of a laser diode be tuned?

The wavelength of a laser diode can be tuned by changing its junction temperature, as the gain maximum is temperature-sensitive. Adjusting the drive current also changes the wavelength, mainly due to the induced temperature change.

What are common types of high-power laser diodes?

Common types include broad area laser diodes emitting a few watts and diode bars, which are arrays producing tens of watts. For even higher powers, multiple bars are combined into diode stacks.

Why can laser diodes be very efficient?

Laser diodes can have very high electrical-to-optical efficiencies, often over 50%, because the electrical pumping process directly injects charge carriers into the active region where they convert to light. This direct conversion process is highly efficient.

What limits the lifetime of a laser diode?

A laser diode's lifetime can be limited by sudden catastrophic optical damage (COD) to the output facet or by gradual degradation from factors like oxidation, the growth of dislocations in the crystal, or degradation of the heat sink.

What are the main applications of laser diodes?

They are widely used in optical data storage (CDs, DVDs, Blu-ray Discs), optical fiber communications, laser pointers, and for pumping solid-state lasers. High-power versions are also used for laser material processing.

What is a VCSEL?

A VCSEL (vertical-cavity surface-emitting laser) is a type of laser diode that emits light perpendicular to the semiconductor wafer surface. VCSELs typically generate a few milliwatts of output power with high beam quality.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 137 suppliers for laser diodes. Among them:

Sacher Lasertechnik offers a wide range of laser diodes:

- Fabry–Pérot laser diodes

- distributed feedback lasers

- AR-coated laser diodes

- microcavity lasers

- VCSELs

Both free-space and fiber-coupled lasers are available.

Alpes Lasers offers SWIR laser diodes emitting at wavelengths from 1.45 to 2.15 μm with powers up to 50 mW. They are offered either as chip-on-carrier or encapsulated in a low power TO-66 package with collimated or divergent free-space beam output.

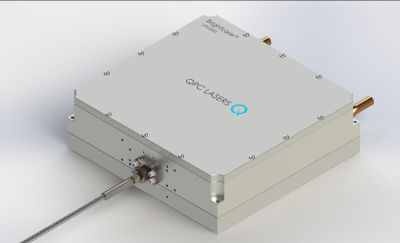

QPC Lasers manufactures diode lasers with the highest powers and brightness in the industry at wavelengths ranging from 780 to 2000 nm.

Full vertical integration from epitaxy through packaging allows us to offer standard and custom diode solutions in packages ranging from C-mounts to complete OEM light engines that provide performance without compromise.

TOPTICA EAGLEYARD is a global leading provider of high power laser diodes with wavelengths from 630–1120 nm based on GaAs (gallium arsenide). Their products combine maximum power, highest durability and excellent beam quality — a perfect match for high-end applications.

Monocrom offers a range of diode lasers for a wide range of wavelengths between 375 nm and 2200 nm:

- single emitters with and without fixed focus

- single-bar lasers

- diode stacks

- horizontal diode laser arrays

- direct diode lasers with up to 8 kW cw

- the LiOM series lasers: short-pulse fiber-coupled lasers for LiDAR applications

Monocrom's solder-free laser bar Clamping™ technique improves the overall performance and prolongs the laser diode lifetime.

CSRayzer offers a wide range of diode lasers, containing diode lasers or diode-pumped lasers with a fiber pigtail or with free-space output.

TOPTICA offers a large variety of wavelength-selected single-mode laser diodes. Among more standard laser diodes you will also find "rarities", i.e. diodes with output wavelengths that only TOPTICA provides. The diodes can be purchased separately. In addition TOPTICA can integrate any diode from the stock lists into a tunable diode laser system: Fabry–Pérot or AR-coated laser diodes may be integrated into a diode laser system, DFB/DBR laser diodes into a DFB pro and Tapered Amplifier into an TA system.

Training: RP personally offers staff training courses on topics like different types of laser diodes, basic properties, and beam shaping — tailored to your needs. Boost the competence and productivity of your team within just a few days!

Consulting: You can get competent advice on many aspects of laser diodes and their use.

Sheaumann Laser offers a wide range of laser diodes, ranging from low-power single-mode emitters to multimode high-power lasers. Many different packaging options (with free-space output or fiber-coupled) are available. Emission wavelengths range from 785 nm to 1710 nm.

Eblana Photonics' core product offerings are based on our proprietary Discrete-Mode platform to achieve excellent performance over a wide wavelength range. Eblana’s DM laser diodes are used in a variety of applications, including gas sensing, LIDAR and telecoms.

Our selection of high-power visible diode lasers (>1.0 W) offer a few key features including high efficiency and long lifetime. Wide temperature range and high optical output power of violet, blue, green, and red lasers. Leading product performance and innovative packaging; their small package size is particularly beneficial to highly compact systems.

RPMC Lasers offers the widest selection of laser diodes, from UV (375 nm) to LWIR (17 µm), in packages ranging from mW-level TO-cans to kW-level fiber-coupled turnkey systems, covering components to subsystems for any application.

Choose from free-space or fiber-coupled outputs with multimode, single-mode, polarized, low-noise, and stabilized options, including SLM, narrow linewidth, and single-frequency designs, plus connector and fiber choices for flexibility.

Tailored solutions include single units and multi-wavelength combiners with up to 7 UV-NIR inputs and 1–4 outputs, available in ultra-compact, portable, USB-powered formats or advanced lab-grade configurations to meet your needs.

Let RPMC help you find the right laser diode today!

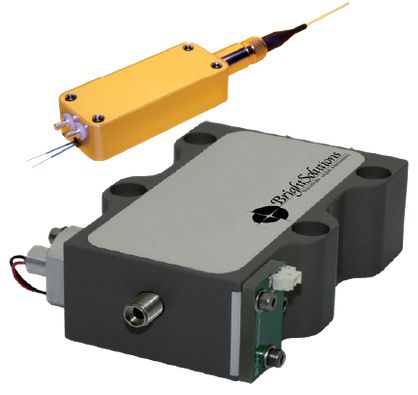

Bright Solutions offers the BDL and BFD — fiber-coupled diode laser modules:

- up to 200 W cw (or 400 W quasi-cw) in a 200-μm core fiber

- flat top beam profile

- integrated TE cooler, current and temperature controller

- optional fiber sensor

- pulsed models are available

They are used e.g. for pumping of solid-state and fiber lasers, material processing or illumination.

Lumibird manufactures a wide range of laser diodes and laser diode modules. Our offering includes QCW diode stacks, CW laser diode modules, fiber coupled QCW diode stacks, short pulse laser diode illuminators, as well as high brightness diode source, IALDA, and pulsed power supply drivers for QCW diodes.

SHIPS TODAY: AeroDIODE offers fiber-coupled laser diodes between 520 nm and 1650 nm as stock items or associated with a CW or pulsed laser diode driver. They are compatible with our high speed nanosecond pulsed drivers or high power CW drivers (with air cooling) for the multimode high power laser diode versions. The single mode laser diodes (either Fabry–Pérot laser diode or DFB laser diode) can reach high power in nanosecond pulse regime up to 500 mW. Most turn-key diode & driver solutions are optimized for single-shot to CW performances with pulse width lengths down to 1 ns. The laser diode precision pulses are generated internally by an on-board pulse generator, or on demand from an external TTL signal. Many multimode versions are available with CW emission up to 300 W in a 200-µm core multimode fiber or up to 250 W in a 135-µm core fiber or 160 W in a 105 µm core fiber.

See also our tutorial on fiber-coupled laser diodes.

Lumics is a vertically integrated manufacturer producing high-quality laser diodes, with in-house chip production and integration into various single emitter packages and designs. Lumics offerings include pigtailed single-mode and multi-mode packages, covering a broad wavelength and power range, designed for different fiber core sizes. Lumics' high-power multi-mode diode laser modules span wavelengths from 670 nm to 1940 nm, supporting multi-wavelength configurations, ideal for applications in medical, life science, analytics, material processing, pumping, seeding, and printing. All diodes feature patented facet technology, ensuring exceptional lifetimes and reliability.

Innolume provides a range of high-performance laser diodes based on GaAs quantum well and quantum dot active regions for emission wavelengths ranging from 780 nm to 1350 nm.

Single-mode applications can be served using distributed feedback (DFB), fiber Bragg grating (FBG), and Fabry–Pérot (FP) lasers in BTF packages.

For pulsed single-mode operations, Innolume offers FP and DFB laser solutions with peak powers up to 1000 mW.

High-power, broad-area laser sources with up to 15 W of output power are available for multimode applications on C- and submount platforms.

Bibliography

| [1] | R. N. Hall et al., “Coherent light emission from GaAs junctions”, Phys. Rev. Lett. 9 (9), 366 (1962); doi:10.1103/PhysRevLett.9.366 |

| [2] | N. Holonyak and S. F. Bevacqua, “Coherent (visible) light emission from Ga(AS1-xPx) junctions”, Appl. Phys. Lett. 1, 82 (1962); doi:10.1063/1.1753706 |

| [3] | J. F. Butler et al., “Properties of the PbSe diode laser”, IEEE J. Quantum Electron. 1 (1), 4 (1965); doi:10.1109/JQE.1965.1072173 |

| [4] | C. A. Wang and S. H. Groves, “New materials for diode laser pumping of solid-state lasers”, IEEE J. Quantum Electron. 28 (4), 942 (1992); doi:10.1109/3.135213 |

| [5] | P. J. Delfyett et al., “High-power ultrafast laser diodes”, IEEE J. Quantum Electron. 28 (10), 2203 (1992); doi:10.1109/3.159528 |

| [6] | J. G. Endriz et al., “High power diode laser arrays”, IEEE J. Quantum Electron. 28 (4), 952 (1992); doi:10.1109/3.135214 |

| [7] | M. Kanskar et al., “73% CW power conversion efficiency at 50 W from 970 nm diode laser bars”, Electron. Lett. 41 (5), 245 (2005); doi:10.1049/el:20058260 |

| [8] | J. V. Moloney et al., “Quantum design of semiconductor active materials: laser and amplifier applications”, Laser & Photon. Rev. 1 (1), 24; doi:10.1002/lpor.200610003 |

| [9] | J. Souto et al., “Mechanisms driving the catastrophic optical damage in high power laser diodes”, Proc. SPIE 9348 (2015); doi:10.1117/12.2079464 |

| [10] | L. Wang et al., “High-power laser diode at 9xx nm with 81.10% efficiency”, Opt. Lett. 47 (13), 3231 (2022); doi:10.1364/OL.452048 |

| [11] | W. W. Chow and S. W. Koch, Semiconductor-Laser Fundamentals, Springer, Berlin (1999) |

| [12] | L. A. Coldren and S. W. Corzine, Diode Lasers and Photonic Integrated Circuits, John Wiley & Sons, New York (1995) |

(Suggest additional literature!)

This encyclopedia is authored by Dr. Rüdiger Paschotta, the founder and executive of RP Photonics AG. How about a tailored training course from this distinguished expert at your location? Contact RP Photonics to find out how his technical consulting services (e.g. product designs, problem solving, independent evaluations, training) and software could become very valuable for your business!

2020-09-08

Could you please give me a hint of why companies offer pump diodes with different wavelengths (e.g. 974.5, 976.0, 977.6, 979.5, 980, 981 nm)? Why it is not just, e.g., 977 nm as a standard?

The author's answer:

We sometimes need somewhat different wavelengths e.g. for pumping different types of laser crystals. Also, it may be difficult to consistently produce laser diodes with a very specific emission wavelength. A manufacturer may then sort the obtained diodes into slightly different wavelength regions and sell them with corresponding specifications.