Transmission Gratings

Definition: diffraction gratings which are used in transmission

More general term: diffraction gratings

Opposite term: reflection gratings

German: Transmissionsgitter

Categories:  general optics,

general optics,  photonic devices

photonic devices

Author: Dr. Rüdiger Paschotta

Cite the article using its DOI: https://doi.org/10.61835/6rl

Get citation code: Endnote (RIS) BibTex plain textHTML

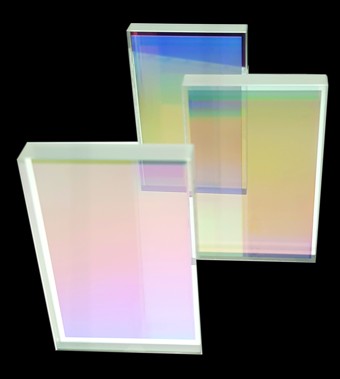

Transmission gratings are diffraction gratings which are used in transmission. This is in contrast to the more common reflection gratings, which reflect all incident light, as far it is not absorbed or scattered.

Transmission gratings can be volume Bragg gratings or surface relief gratings. The latter have a diffractive structure at or near one of their surfaces. See the article on diffraction gratings concerning fabrication methods.

Operation Principle

The operation principle of all diffraction gratings, including transmission gratings, is based on the diffraction of light. However, for transmission gratings the application of that principle differs in some respects from the situation of reflection gratings:

Light Transmission Through Materials

A transmission grating must be fabricated from a well transparent medium, i.e., with low absorption and scattering losses. This is an easily met condition for visible and near-infrared light, but means stringent limitations for the choice of optical materials in other spectral regions such as the far ultraviolet and the far infrared.

In many cases, one fabricates transmission gratings based on robust optical materials (mostly glasses) with high optical quality and well established processing methods. A particularly prominent example is fused silica, which also exhibits a very wide spectral transmission range.

Fresnel Reflections

It is also usually necessary to suppress Fresnel reflections, e.g. with an anti-reflection coating. Unfortunately, such coatings can have a high performance only in a limited angular and spectral range. Therefore, one sometimes uses uncoated gratings, accepting a certain amount of reflection losses.

Limited Angular Range

While a high reflectance of a reflection grating, e.g. containing a metallic reflector, can be achieved over a wide range of angles of incidence, it is more difficult to obtain low reflection losses of a transmission grating over a large angular range. This is one of the reasons why transmission gratings are often designed with a lower line density such as to limit the angular range of the involved beams. Of course, the applications need to be adapted accordingly.

As long as the beam angles against the surface are close to perpendicular, a low polarization sensitivity can also be achieved.

Achieving Strong Enough Phase Modulation

For transmission gratings, it is more difficult to achieve a strong enough modulation of optical phase of the grating structure. This is easily understood by considering that all involved beams are essentially co-propagating, and accumulated phase changes are determined not by geometrical path length differences, but by the product of a difference in refractive index and the propagation length. Here, the involved refractive index difference is often well below 1. In contrast, a relief grating structure operated in reflection leads to phase differences which are proportional to twice the relief height, corresponding to contributions from a forward and backward pass of light e.g. through air. Therefore, surface relief structures for transmission gratings typically require a several times higher aspect ratio (depth / line spacing) for achieving a similar diffraction efficiency.

Avoiding Absorption in Metals

On the other hand, problems related to the use of metallic reflecting structures are avoided – in particular, the increasing absorption at short optical wavelengths. Transmission gratings may be fabricated entirely from one or more dielectric materials with very low absorption coefficients. These materials and also exhibit a much higher threshold for laser-induced damage.

Optical Performance of Diffraction Gratings

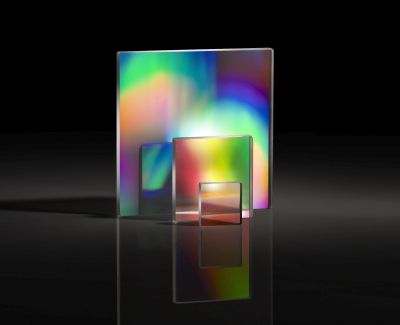

Despite the challenges explained above, it has become possible to produce transmission gratings with very high performance – particularly with holographic techniques, in optimized forms allowing for structures with extreme aspect ratios. They can achieve a very high diffraction efficiency, defined as the optical power sent into the desired diffraction order divided by the incident power. This is particularly important for certain applications like pulse compressors for ultrashort pulses, where losses at compressor gratings reduce the available output power and at the same time may introduce thermal problems. Diffraction efficiencies far above 90% and very low stray light are possible in wide wavelength regions, and even efficiencies beyond 98% are sometimes achieved.

At the same time, low levels of stray light can be obtained, and the threshold for laser-induced damage can be pretty high. Compared with holographic volume gratings, the temperature sensitivity is typically much lower.

Alignment Properties

Concerning the alignment sensitivity, apparatuses based on transmission gratings are often far more forgiving than those using reflection gratings. It is easy to see that the zero-order (non-diffracted) beam has the same direction as the input beam, if the grating device has parallel surfaces. Any angular alignment error can only lead to a slight displacement of that beam. The diffracted beams are also affected by misalignment only to a small extent.

In comparison, the output angle of the zero-order beam of a reflection grating is changed by twice the angular shift of the grating, just as for an ordinary mirror, and the diffracted beams are also strongly affected.

Of course, a detailed comparison also needs to take into account possibly quite different line spacings of the gratings.

Practical Aspects

An often important practical aspect of operating a grating in transmission is that the diffracted light is better separated from the incoming light. It thus becomes much easier, for example, to mount a light detector (e.g. a focal plane array) without obstructing the path of the incident light, and the resulting device design, e.g. of a spectrometer, may become more compact.

Using a transmission grating, it is even possible to convert various types of imaging instruments into spectrometers, since the beam path is not profoundly altered.

Special Forms

Most transmission gratings have a structure of equidistant lines on a plane surface. However, it is also possible to make gratings on curved surfaces and/or to vary the line spacing.

For some applications e.g. in spectroscopy and pulse compressors, it is convenient to use a so-called grisms, which is a prism equipped with a diffractive structure on one of its surfaces.

It is also possible to fabricate two-dimensional gratings (2D transmission gratings) which can diffract beams into two dimensions. Some of those are used, for example, as optical pattern generators.

Typical Applications

Some typical applications of transmission gratings are briefly discussed in the following:

- There are compact spectrometer designs based on transmission gratings, e.g. in combination with a focal plane array of high spatial resolution. A high diffraction efficiency is important for a high measurement sensitivity.

- Pulse compressors for ultrashort pulses are used e.g. in chirped-pulse amplification systems. They particularly profit from very high diffraction efficiencies as are possible with optimized gratings.

- Transmission gratings can also be used as beam splitters for monochromatic light sources like lasers.

- Some transmission gratings are used as optical pattern generators in one or two dimensions.

More to Learn

Encyclopedia articles:

Suppliers

The RP Photonics Buyer's Guide contains 18 suppliers for transmission gratings. Among them:

Holographix

Using advanced design and manufacturing processes, Holographix produces custom surface relief transmission gratings that consistently meet or exceed the performance of volume gratings, but at a fraction of the cost!

Gitterwerk

Gitterwerk’s transmission grating provides a perfect solution for ultra-high-power and ultra-short pulse lasers with maximum efficiency (up to 99.5%). With our new technology, you will get the best gratings without any stitching problems or period variations up to 135 mm diameter, available for high-volume production, as well as customizable requests. We cover the spectrum from 250 nm – 2500 nm with a series of line densities ranging from 600 l/mm up to 3000 l/mm.

Edmund Optics

Edmund Optics offers different products for Transmissive Diffraction Gratings, like Transmission Grating that are ideal for In-Line Configurations, UV Transmission Gratings that are ideal for Fixed Grating Applications or Transmission Grating Beamsplitters ideal for Laser Beam Division.

Bibliography

| [1] | W. A. Traub, “Constant-dispersion grism spectrometer for channeled spectra”, J. Opt. Soc. Am. A 7 (9), 1779 (1990); https://doi.org/10.1364/JOSAA.7.001779 |

| [2] | H. Nguyen et al., “High-efficiency fused-silica transmission gratings”, Opt. Lett. 22 (3), 142 (1997); https://doi.org/10.1364/OL.22.000142 |

| [3] | T. Clausnitzer et al., “Highly efficient transmission gratings in fused silica for chirped-pulse amplification systems”, Appl. Opt. 42 (34), 6934 (2003); https://doi.org/10.1364/AO.42.006934 |

| [4] | N. Bonod and J. Neauport, “Diffraction gratings: from principles to applications in high-intensity lasers”, Advances in Optics and Photonics 8 (1), 156 (2016); https://doi.org/10.1364/AOP.8.000156 |

| [5] | T. P. Rasmussen, “Compact and high performance spectrometers based on novel transmission gratings with high dispersion”, Appl. Spectroscopy 70 (5), 804 (2016) |

| [6] | J. E. Harvey and R. N. Pfisterer, “Understanding diffraction grating behavior: including conical diffraction and Rayleigh anomalies from transmission gratings”, Optical Engineering 58 (8), 087105 (2019); https://doi.org/10.1117/1.OE.58.8.087105 |

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

Connect and share this with your network:

Follow our specific LinkedIn pages for more insights and updates: