CO2 Lasers

Definition: infrared lasers based on a gas mixture in which light is amplified by carbon dioxide molecules

Alternative term: carbon dioxide lasers

German: CO2-Laser, Kohlendioxidlaser

Category:  laser devices and laser physics

laser devices and laser physics

Author: Dr. Rüdiger Paschotta

Cite the article using its DOI: https://doi.org/10.61835/u9k

Get citation code: Endnote (RIS) BibTex plain textHTML

The CO2 laser (carbon dioxide laser) is a molecular gas laser with emission in the long-wavelength infrared spectral region. It is based on a gas mixture as the gain medium, which contains carbon dioxide (CO2), helium (He), nitrogen (N2), and possibly some hydrogen (H2), oxygen (O2), water vapor and/or xenon (Xe). Such a laser is electrically pumped via an electrical gas discharge, which can be operated with DC current, with AC current (e.g. 20–50 kHz) or in the radio frequency (RF) domain.

Although direct excitation of CO2 molecules into the upper laser level is possible, it has proven to be most efficient to use a resonant energy transfer from nitrogen molecules. Here, nitrogen molecules are excited by the electric discharge into a metastable vibrational level and transfer their excitation energy to the CO2 molecules when colliding with them. The exited CO2 molecules then largely participate in the laser transition. Helium serves both to depopulate the lower laser level and to remove the heat. Other constituents such as hydrogen or water vapor can help (particularly in sealed-tube lasers) to reoxidize carbon monoxide (CO, formed in the discharge) to carbon dioxide.

Spectral Lines

CO2 lasers typically emit at a wavelength of 10.6 μm, but there are dozens of other laser lines in the region of 9–11 μm (particularly at 9.6 μm). This is because two different vibrational states of the CO2 molecules can be used as the lower level, and for each vibrational state, there is a substantial number of rotational states, leading to many sub-levels. Dipole transitions (the only ones with a relatively high strength) are possible with <$\Delta J$> = ±1, where <$\Delta J = 1$> (R branch) leads to higher photon energies (shorter wavelengths) and <$\Delta J = -1$> (P branch) to lower energies:

- Transitions of the stronger band, involving one of the two possible final vibrational levels, have their P branch around 10.6 μm, with P20 being the dominant transition, and the R branch around 10.2 μm.

- Transitions of the other band have the P branch around 9.6 μm and the R branch around 9.3 μm.

With a suitable wavelength tuning element in the laser resonator, a CO2 laser can be made to lase on one of more than a dozen transitions with relatively closely spaced wavelengths in each branch, but continuous wavelength tuning is not possible due to the discrete rotational states of the molecules. Without a wavelength-selective element in the resonator, one may obtain simultaneous lasing on a few transitions, or occasional jumps to other transitions during operation.

While most commercially available CO2 lasers emit at the standard wavelength of 10.6 μm, there are devices which are specially optimized for other wavelengths such as 10.25 μm or 9.3 μm, which are far better suited for certain applications for example in laser material processing because that radiation is much more absorbed in certain materials (e.g. polymers). For making such lasers and for using their radiation, one may require special infrared optics, as standard transmissive 10.6-μm optics may e.g. exhibit too strong reflections.

All CO2 laser emissions lines can be considered to be in the long-wavelength infrared region, which is part of the mid-infrared region according to ISO 20473:2007.

Output Powers and Efficiency

In most cases, average output powers are between some tens of watts and many kilowatts. The power conversion efficiency can be around 10% to 20%, i.e., it is higher than for most gas lasers (due to a particularly favorable excitation pathway), also higher than for lamp-pumped solid-state lasers, but lower than for many diode-pumped lasers.

Due to their high output powers and long emission wavelengths, CO2 lasers require high-quality infrared optics, often made of materials like zinc selenide (ZnSe) or zinc sulfide (ZnS).

Due to their high powers and high drive voltages, CO2 lasers raise serious issues of laser safety. However, their long operation wavelength makes them relatively eye-safe at low intensities.

CO2 Laser Types

The family of CO2 lasers is very diverse:

- For laser powers between a few watts and a several hundred watts, it is common to use sealed-tube or no-flow lasers, where the laser bore and gas supply are contained in a sealed tube. Waste heat is transported to the tube walls by diffusion (with a quite helpful effect of the helium) or a slow gas flow. Such lasers are compact and rugged, and easily reach operation lifetimes of several thousands of hours or more. Here, one needs to employ methods for continuously regenerating the gas – in particular, for counteracting the dissociation of CO2 by catalytic re-oxidization of CO. The beam quality can be very high.

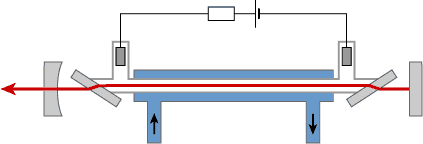

- High-power diffusion-cooled slab lasers (not to be confused with solid-state slab lasers) have the gas in a gap between a pair of planar water-cooled RF electrodes. The excess heat is efficiently transferred to the electrodes by diffusion, if the electrode spacing is made small compared with the electrode width. For efficient energy extraction, one often uses an unstable resonator with output coupling at the side of a highly reflecting mirror. Several kilowatts of output are possible in conjunction with reasonable beam quality.

- Fast axial flow lasers and fast transverse flow lasers are also suitable for multi-kilowatt continuous-wave output powers and high beam quality. The excess heat is removed by the fast-flowing gas mixture, which passes an external cooler (heat exchanger) before being used again in the discharge. The gas can be continuously regenerated and occasionally replaced. Transverse flow lasers reach highest output powers, but typically with lower beam quality.

- Transverse excited atmosphere (TEA) lasers have a very high (about atmospheric) gas pressure. As the voltage required for a longitudinal discharge would be too high, transverse excitation is done with a series of electrodes along the tube. TEA lasers are operated in pulsed mode only, as the gas discharge would not be stable at high pressures. They often produce average output powers below 100 W, but can also be made for powers of tens of kilowatts (combined with high pulse repetition rates).

- There are gas dynamic CO2 lasers (a kind of chemical lasers) for multi-megawatt powers (e.g. for anti-missile weapons), where the energy is not provided by a gas discharge but by a chemical reaction in a kind of rocket engine.

These concepts lead to quite different laser architectures, with specific strengths and weaknesses concerning output power potential, beam quality, gas consumption and device lifetime.

Applications of CO2 Lasers

CO2 lasers are widely used as industrial lasers for laser material processing, in particular for

- cutting and structuring plastic materials, wood, die boards, glass pieces, etc., which exhibit high absorption at 10.6 μm, mostly applying moderate power levels of 20–200 W

- cutting, welding and cladding metals such as stainless steel, aluminum or copper, applying multi-kilowatt powers

- laser marking of various materials

- laser hardening e.g. of machine parts made of steel

- laser soldering in electronics

- laser 3D printing of polymer materials

Other applications include laser surgery (including ophthalmology), range finding (LIDAR) and spectroscopy.

Competition with Solid-state Lasers

CO2 lasers used for laser material processing (e.g. welding and cutting of metals, or laser marking) are in competition with solid-state lasers (particularly YAG lasers and fiber lasers) operating in the 1-μm wavelength regime. These shorter wavelengths have the advantages of more efficient absorption in a metallic workpiece and the potential for beam delivery via fiber cables. (There are no optical fibers for high-power 10-μm laser beams, since there are no suitable materials with very high transparency in that region.) Besides, 1-μm beams can be more tightly focused, provided that the beam quality is high. However, the latter potential normally cannot be realized with high-power lamp-pumped lasers, and diode-pumped lasers tend to be more expensive. Concerning absorption, CO2 laser beams are actually quite favorable for certain materials like polymers and ceramics. Even when absorption is less favorable than for a solid-state laser, a CO2 laser may be preferred as a relatively cheap and robust solution. A substantial disadvantage, however, is that there are no high-power fiber cables for CO2 laser radiation.

CO2 lasers are still widely used in the cutting and welding business, particularly for parts with a thickness greater than a few millimeters, and their sales still make a substantial part of all global laser sales. This may to some extent change in the future due to the development of high-power thin-disk lasers and advanced fiber cables in combination with techniques which exploit the high beam quality of such lasers.

More to Learn

Encyclopedia articles:

Bibliography

| [1] | C. K. N. Patel, “Continuous-wave laser action on vibrational–rotational transitions of CO2”, Phys. Rev. 136 (5A), A1187 (1964); https://doi.org/10.1103/PhysRev.136.A1187 |

| [2] | C. K. N. Patel, “Interpretation of CO2 optical maser experiments”, Phys. Rev. Lett. 12 (21), 588 (1964); https://doi.org/10.1103/PhysRevLett.12.588 |

| [3] | C. K. N. Patel, “CW high-power N2-CO2 laser,” Appl. Phys. Lett. 7 (1), 15 (1965); https://doi.org/10.1063/1.1754233 |

| [4] | A. Robinson and D. Johnson, “A carbon dioxide laser bibliography, 1964–1969”, IEEE J. Quantum Electron. 6 (10), 590 (1970); https://doi.org/10.1109/JQE.1970.1076334 |

| [5] | P. T. Woods et al., “Stable single-frequency carbon dioxide lasers”, J. Phys. E: Sci. Instrum. 9, 395 (1976); https://doi.org/10.1088/0022-3735/9/5/021 |

| [6] | A. L. S. Smith and J. Mellis, “Operating efficiencies in pulsed carbon dioxide lasers”, Appl. Phys. Lett. 41, 1037 (1982); https://doi.org/10.1063/1.93385 |

| [7] | K. M. Abramski et al., “Power scaling of large-area transverse radiofrequency discharge CO2 lasers”, Appl. Phys. Lett. 54, 1833 (1989); https://doi.org/10.1063/1.101250 |

| [8] | C. Fromentin et al., “Validation of non-equilibrium kinetics in CO2–N2 plasmas”, Plasma Sources Sci. Technol. 32, 054004 (2023); https://doi.org/10.1088/1361-6595/acce64 |

| [9] | O. Svelto, Principles of Lasers, Plenum Press, New York (1998) |

Questions and Comments from Users

2022-04-07

Why are CO2 lasers generally not used for metals like copper?

The author's answer:

The absorption of copper around 10.6 μm is very weak, so that you cannot effectively use the laser radiation. Well, there are ways of solving that problem with an absorbing layer deposited on the copper, but that approach has its own disadvantages.

2023-06-17

Can a wavelength of 10.6 μm still be regarded as infrared? I consider that as being well in the microwave territory.

The author's answer:

No, that's clearly infrared, far outside the microwave region. The optical frequency is 28.3 THz, while microwaves reach only up to about 300 GHz = 0.3 THz.

2023-06-22

A commonly-stated benefit of CO2 lasers is that they can generate high average power levels. But why are they good at that? For a fiber, we can say that it has excellent thermal management due to the large surface area. What is the reason for a CO2 laser?

The author's answer:

A direct comparison with fiber lasers is difficult due to the many important differences. But a very helpful factor for CO2 lasers is the relatively efficient power conversion combined with efficient heat removal e.g. via fast gas flow.

2023-09-26

Why is it not efficient to directly excite the CO2 molecules?

The author's answer:

That's a difficult question, but you can find out more on that in a newly added reference in the bibliography (Fromentin et al.).

2023-11-28

Are there any other known emitters of the 10.6 μm wavelength?

The author's answer:

Yes, that can be achieved with quantum cascade lasers (but at far lower power levels) or with optical parametric oscillators (also with lower power).

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

2020-11-30

What is the typical lifetime of a CO2 laser?

The author's answer:

It would not be helpful to specify a typical lifetime because that depends very much on various factors such as the construction of the tube, pulsed or continuous emission, and the detailed operation parameters. For some industrial lasers, the tube lasts for thousands of hours, and after exchanging that the laser may again operate for a long time.