Ultraviolet Optics

Acronym: UV optics

Definition: optical elements for use with ultraviolet light

More general term: optics

German: Ultraviolett-Optik

Author: Dr. Rüdiger Paschotta

Cite the article using its DOI: https://doi.org/10.61835/pyp

Get citation code: Endnote (RIS) BibTex plain textHTML

Ultraviolet light behaves in many ways just as visible light, and it can thus in principle be used with the same times of optical elements as visible or near-infrared light: focusing and imaging lenses, mirrors, optical windows, beam splitters, prisms, polarizers, waveplates, optical filters etc. UV mirrors and lenses are also available in aspheric versions, and anti-reflection coatings are available. However, there are certain special aspects to be observed for applications in the UV region:

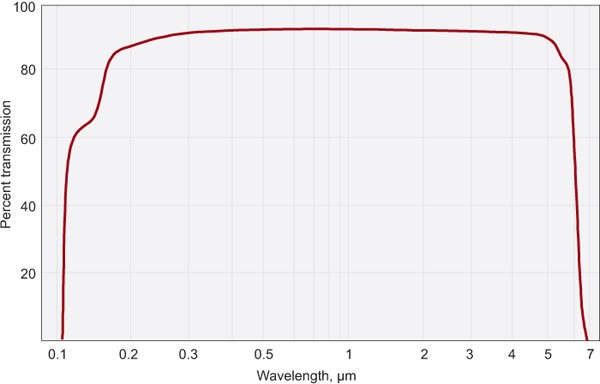

- Transparency range: Many optical media which are transparent for visible light become strongly absorbing when one penetrates the ultraviolet spectral region with optical wavelengths below 400 nm. This is essentially because the photon energy then becomes comparable to the band gap energy; a single photon is then sufficient for exciting a carrier from the valence band to the conduction band. Therefore, transparency in the ultraviolet spectral region can be obtained only with dielectric media having a relatively large bandgap. Examples are certain crystalline optical materials (optical crystals) like CaF2 and some borates.

- Even if the bandgap energy of a medium is large enough, there may be substantial UV absorption due to impurities.

- For really short wavelengths (EUV), there are no suitable transparent media anymore, and one is limited to reflective optics (see below).

- Below about 200 nm wavelength, even air becomes absorbing, so that UV systems for far-UV light need to be evacuated.

- Scattering: Due to the very short wavelengths, ultraviolet light experiences strong scattering even at very tiny imperfections such as scratches on optical services or inhomogeneities within a medium. For example, scattering at very small (sub-wavelength) particles scales with λ−4, getting dramatically stronger for shorter wavelengths. Therefore, a particularly high optical quality of components is required to keep potentially detrimental processes like scattering and beam distortions under control in the ultraviolet. Important material parameters for UV applications are a low bubble and inclusion content, good homogeneity of the refractive index, a small parasitic birefringence. Further, materials should have the potential for polishing surfaces with very small roughness.

- Damage and degradation: Particularly for applications with intense UV lasers, the risk of laser damage and of long-term degradation (solarization) is also important: the propagation losses rise, and increased light scattering is observed. Various media are known to exhibit significant degradation effects – for example, absorption or scattering losses increasing with time during UV radiation –, but some materials are relatively tolerant against UV light. (There are also solarization-resistant fibers.) The optical damage threshold of materials is often substantially lower in the UV than for longer wavelengths because lower-order absorption processes (e.g. two-photon absorption) are sufficient to bridge the bandgap. Damage and degradation phenomena can strongly depend on certain impurities in the material and on the details of the optical surface finishing.

- Note also that any optical surfaces can be degraded e.g. if vapors from lubrication oils get into an intense ultraviolet beam, where certain substances are chemically decomposed and can consequently form absorbing coatings on nearby materials.

- Dispersion effects: In the ultraviolet spectral region, many media exhibit substantially stronger chromatic dispersion than in the visible or infrared region. This must be observed, for example, when using lenses for focusing broadband ultraviolet light. Using achromatic optics can then be particularly important.

Examples of UV-transparent Media

UV optics are often made from highly purified calcium fluoride (CaF2), which has a very low UV absorption, high homogeneity, low birefringence, relatively high hardness (compared with other fluoride materials), high physical stability, and high optical damage threshold. It can be used down to ≈ 160 nm and is thus suitable for use, e.g., with argon fluoride (ArF) excimer lasers. However, it is brittle, naturally anisotropic, and hygroscopic. Similar properties are obtained for other purified fluorides such as magnesium fluoride (MgF2) and lithium fluoride (LiF); the latter can be used down to 110 nm. In addition to good UV transparency, such fluorides also offer good infrared properties up to wavelengths of 5 μm and beyond.

As an alternative, UV-grade fused silica can be used even for wavelengths down to ≈ 180 nm, whereas other grades of fused silica have significant attenuation already below 260 nm.

Similar constraints apply to materials chosen for making dielectric coatings, for example in the form of anti-reflection coatings. A frequently used AR coating material is magnesium fluoride (MgF2). Often, manufacturers offer UV anti-reflection coatings without revealing what material(s) they are made of.

Another possible material choice is artificial diamond, which is transparent down to ≈ 230 nm and very robust, but expensive.

For nonlinear frequency conversion, one often uses borate crystals such as LBO and BBO, which exhibit relatively good UV transparency and high resistance.

Some optical fibers can be used in the near-ultraviolet spectral region, although with relatively high propagation losses. Fiber delivery of ultraviolet light is usually not feasible for shorter wavelengths and/or high optical powers.

Common UV Wavelengths

In laser technology, a few ultraviolet wavelengths are particularly common:

- 355 nm is obtained by frequency tripling of Nd:YAG lasers

- 266 nm is obtained by frequency quadrupling of Nd:YAG lasers

- 193 nm and a few other wavelengths are made by certain types of excimer lasers.

Therefore, certain optical elements like lenses and mirrors are specifically developed for such wavelengths and may then be sold as excimer optics, for example.

EUV Optics: Essentially Limited to Reflective Optics

In the EUV region, basically all solid materials are relatively strongly absorbing, and even air causes strong attenuation below ≈ 200 nm, so that e.g. lithography with vacuum UV or EUV light below 100 nm has to be performed in vacuum. Bragg mirrors can still be made for the EUV region, e.g. with molybdenum/silicon (Mo/Si) structures, which allow, e.g., ≈ 70% reflectivity at 12 nm wavelength to be reached. Due to this limited reflectivity, EUV optics have to be designed with the smallest possible number of reflecting surfaces.

More to Learn

Encyclopedia articles:

Suppliers

The RP Photonics Buyer's Guide contains 72 suppliers for ultraviolet optics. Among them:

Universe Kogaku

Universe Kogaku offers UV lenses and lens design for electronics, optics, medical and precision industrial applications. For example, we have deep UV lenses optimized for 250 nm wavelength, available from stock with focal lengths from 6 mm to 105 mm.

We have designed and manufactured these lenses as a reasonably priced solution to the growing need for imaging outside the visible spectral region. Owing to the broad transmission range of the elements, this family of lenses can transmit well in the infrared spectral region as well.

LASEROPTIK

LASEROPTIK offers excimer optics coatings of various types – anti-reflection (VAR), high reflection (HR), thin-film polarizer (TFP) and variable attenuator (VA). This can be done for many UV wavelengths like 157 nm, 172 nm, 126 nm and others.

Knight Optical

Knight Optical has been providing optical components suitable for UV applications for many years. By utilising substrates that transmit into the UV waveband or applying a coating that enhances the optics performance in the lower wavelengths optics can be designed to work in these lower wavelengths. Substrates include UV fused silica, calcium fluoride, magnesium fluoride, lithium fluoride, calcite, and sapphire. Optics include windows, lenses, mirrors, and filters. Knight Optical has stock and custom options available for our customers.

UltraFast Innovations

UltraFast Innovations (UFI) has a range of dielectric mirrors, some of which cover parts of the ultraviolet region. For example, we have XUV (extreme ultraviolet) and soft X-ray multilayer mirrors which are suitable e.g. for at the second pulse generation and pulse shaping based on high harmonic generation (HHG). Our design know-how and application experience gained through a strong collaboration with numerous scientists within these fields allows us to provide custom support for the planning of your setup and the realization of advanced unique experiments.

Edmund Optics

Edmund Optics is a premier supplier of UV optics including mirrors, lenses, filters, and beam expanders. We work with ISO 9001 certified and MIL-spec quality systems, and use a wide range of metrology including interferometers, cavity ring-down (CRD) spectrometers, Shack–Hartmann wavefront sensors, profilometers, and coordinate measurement machines (CMMs). We provided guaranteed laser damage threshold specifications.

Avantier

Avantier designs and produces custom optical components with tailored substrates and coatings optimized for superior performance across various wavelengths, including UV, visible, SWIR, MWIR, and LWIR. We ensure the highest quality and top-notch performance of our optical components using cutting-edge metrology technology.

OPTOMAN

OPTOMAN can manufacture custom dielectric thin films and high-power laser optics for UV applications starting from 193 nm. Various type of coatings – anti-reflection, thin-film polarizer, broadband or laser line high reflectivity – can be optimized for your application.

GLOphotonics

Explore the distinctive hollow-core photonic crystal fiber technology, guiding light within a hollow channel and enveloped by a microstructured cladding. A unique approach that redefines precision and efficiency in the field of photonics (from 213 nm to mid-infrared).

As a trailblazing industrial leader, GLO takes the forefront in photonics with a diverse array of hollow-core photonic crystal Fiber solutions, tailored to meet the unique needs of our valued partners. Our commitment lies in delivering bespoke HCPCF innovations, setting new standards in the industry.

EKSMA OPTICS

EKSMA Optics has substrates and finished optical components for the ultraviolet – windows, lenses and mirrors made from lithium fluoride (LiF), calcium fluoride (CaF2), barium fluoride (BaF2) and sapphire (Al2O3) for laser and optical instruments applications in the UV wavelength range.

Shanghai Optics

Shanghai Optics custom-made optical components are designed with specific substrates, custom coatings to optimize the performance in UV, visible, SWIR, MWIR, LWIR wavelength. With the help of state-of-the-art metrology, Shanghai Optics is committed to high quality and top performance optical components.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here; we would otherwise delete it soon. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

general optics

general optics

Connect and share this with your network:

Follow our specific LinkedIn pages for more insights and updates: